Mastering Pipe Identification: A Comprehensive Guide to Brady Pipe Marking Solutions

Posted by Advanced Automation on Jan 19th 2026

In the fast-paced world of industrial operations, safety, compliance, and efficiency are non-negotiable. At Advanced Automation Inc., we specialize in delivering cutting-edge automation and identification solutions to streamline your processes. One critical aspect often overlooked until a crisis hits is proper pipe identification. Enter Brady pipe marking solutions – a powerhouse in labeling, signing, and tagging that ensures your facility runs smoothly while meeting rigorous standards. This guide dives deep into the essentials of pipe marking from a labeling perspective, explores its challenges, and highlights how Brady's innovative products rise to the occasion. Whether you're managing a manufacturing plant, chemical facility, or utility system, understanding these solutions can transform potential hazards into well-organized assets.

Understanding Pipe Marking: The Labeling Perspective

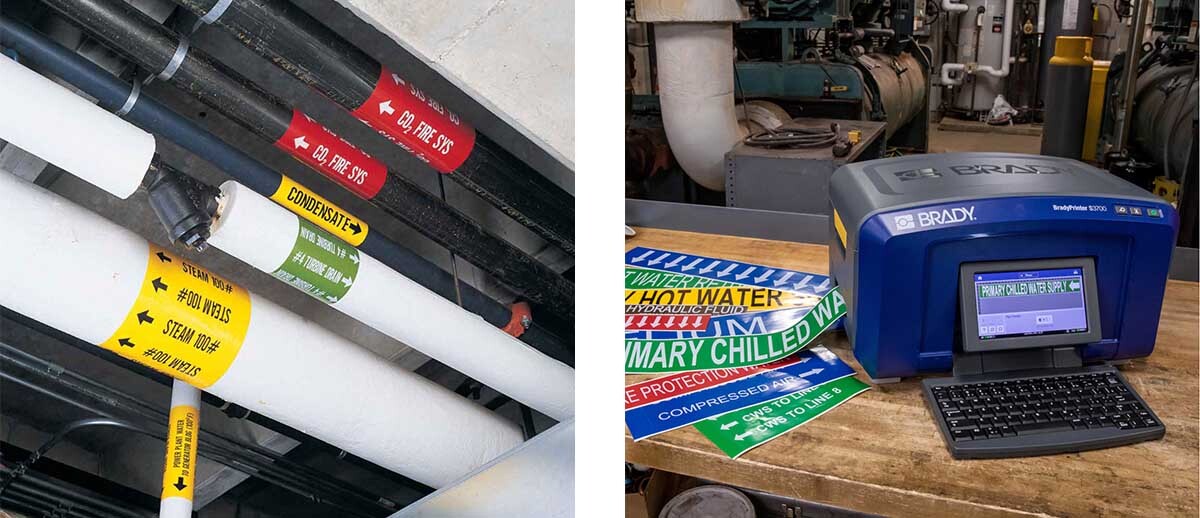

From a sign and labeling viewpoint, pipe marking involves the strategic application of visual identifiers – such as labels, signs, tags, and markers – to pipes and conduits carrying fluids, gases, or other substances. These identifiers typically include color-coded bands, directional arrows, text descriptions of contents, and hazard warnings. The goal is to create a clear, at-a-glance system that communicates vital information to workers, emergency responders, and maintenance teams.

Think of pipe marking as the silent guardian of your infrastructure. It's not just about sticking a label on a pipe; it's about engineering a durable, compliant communication tool that withstands environmental stresses while conveying precise details. Standards like ANSI/ASME A13.1 dictate color schemes (e.g., yellow for flammable materials, blue for potable water) and label formats, ensuring uniformity across industries. In essence, pipe marking turns complex networks of pipes into readable maps, reducing confusion and enhancing operational flow.

The Purpose and Necessity of Pipe Marking

Why invest time and resources into pipe marking? At its core, it's done to promote safety, facilitate maintenance, and ensure regulatory compliance. In high-stakes environments like oil refineries, wastewater treatment plants, or food processing facilities, misidentified pipes can lead to catastrophic errors – from chemical spills to equipment failures.

Necessity stems from both legal mandates and practical benefits. Regulations such as OSHA 1910.261 require visible pipe identification to prevent accidents, while NFPA 99 for healthcare facilities emphasizes clear labeling for medical gases. Beyond compliance, effective pipe marking minimizes downtime during repairs, aids in quick emergency responses, and boosts overall workplace efficiency. Imagine a scenario where first responders can instantly identify a leaking pipe's contents; that's the life-saving power of proper labeling. In an era of increasing scrutiny on industrial safety, skipping this step isn't just risky – it's potentially costly in fines, lawsuits, and lost productivity.

Challenges and Difficulties in Pipe Marking

Pipe marking isn't always straightforward. Several factors can complicate the process, turning a simple labeling task into a logistical headache. First, environmental exposure poses a major hurdle. Pipes in outdoor or industrial settings face extreme temperatures, UV radiation, moisture, chemicals, and abrasion, which can degrade standard labels over time, leading to faded text or peeling adhesives.

Space constraints add another layer of difficulty. In crowded facilities with intertwined pipe networks, finding room for legible markers without obstructing access is tricky. Curved surfaces, irregular diameters, and hard-to-reach locations demand flexible, adaptable solutions that standard flat labels can't provide.

Compliance variability is yet another challenge. Different industries have unique requirements – for instance, marine environments need saltwater-resistant materials, while pharmaceutical plants require non-contaminating labels. Incorrect color coding or incomplete information can result in non-compliance, inviting audits and penalties.

Finally, installation and maintenance logistics can be daunting. Applying labels in confined spaces or during operational hours requires tools that are quick to install yet long-lasting, without disrupting workflows. Overlooking these challenges often leads to makeshift solutions that fail prematurely, exacerbating risks.

The Case for Durable Labeling and Tagging Over Standard Paper

Absolutely, pipe markers frequently demand far more robust solutions than standard paper labels. Paper is inexpensive and easy to print, but it crumbles under real-world industrial demands. It absorbs moisture, tears easily, and fades under sunlight or chemical exposure, rendering it useless in harsh conditions.

Durable alternatives, like vinyl, polyester, or metal tags, offer superior resistance. These materials maintain integrity in temperatures ranging from -40°F to 300°F, repel oils and solvents, and adhere strongly to greasy or textured surfaces. For instance, self-laminating labels protect printed information from smudges and abrasion, while snap-on markers provide a no-adhesive option for quick application. In environments with frequent cleaning or high vibration, these advanced solutions ensure longevity, reducing replacement frequency and total cost of ownership. Transitioning from paper to durable options isn't just an upgrade – it's a strategic move for sustained safety and efficiency.

Exploring Brady ID's Pipe Marking Solutions: Materials, Features, and Challenge Overcomes

Brady ID, a leader in identification products, offers a comprehensive suite of pipe marking solutions tailored to conquer the toughest industrial challenges. Their portfolio includes labels, signs, tags, and accessories designed for durability, ease of use, and compliance. Let's break down some key offerings and how they address common pain points.

Starting with Brady's B-689 High-Performance Polyester Pipe Markers, these are engineered for demanding environments. Made from coiled polyester with a strong acrylic adhesive, they wrap around pipes of various diameters without creasing. The material resists fading from UV light and chemicals, overcoming exposure challenges in outdoor or corrosive settings. For end-users in chemical plants, these markers ensure labels remain legible for years, preventing misidentification during maintenance.

For quick, tool-free installation, Brady's Snap-On Pipe Markers are a game-changer. Constructed from durable plastic, they clip onto pipes ranging from 0.75" to over 8" in diameter. This design tackles space and accessibility issues, allowing application in tight spots without surface preparation. In facilities with frequent inspections, like power plants, these markers save time and reduce labor costs while maintaining ANSI compliance.

Brady also excels in customizable solutions, such as their Opti-Code™ Self-Adhesive Pipe Markers. These vinyl labels feature pre-printed legends with color bands and arrows, printable on-site for specific needs. The vinyl material is abrasion-resistant and adheres to dirty surfaces, addressing adhesion challenges on oily pipes. End-users in manufacturing benefit from this flexibility, creating tailored labels that enhance workflow efficiency and safety protocols.

For extreme durability, consider Brady's Rigid Aluminum Pipe Markers or Stainless Steel Tags. Aluminum signs withstand high heat and impacts, ideal for boiler rooms or refineries, while stainless steel tags resist corrosion in marine or food processing applications. These metal options surpass paper by offering permanence against vandalism or accidental damage, ensuring long-term reliability.

Brady's Lockout/Tagout (LOTO) integration adds another layer, with tags that double as safety devices during maintenance. Materials like laminated polyester prevent tampering, overcoming challenges in high-security environments.

What sets Brady apart is their focus on overcoming end-user challenges holistically. Their solutions incorporate fade-resistant inks, low-halogen materials for eco-friendliness, and compatibility with printers like the Brady BMP®71 for on-demand creation. By providing kits with arrows, bands, and legends, Brady simplifies inventory management. In essence, these products not only meet but exceed standards, turning potential vulnerabilities into strengths for safer, more efficient operations.

Key Questions to Determine When to Prioritize Pipe Marking

Knowing when to elevate pipe marking from a checklist item to a strategic priority can prevent issues before they escalate. Here are 3-5 essential questions every company should ask:

- Are our current labels holding up in real conditions? If fading, peeling, or illegibility is common after a few months, it's time for durable upgrades to avoid compliance risks.

- Have we experienced near-misses or incidents due to pipe misidentification? Any close calls signal the need for clearer, more robust marking systems to enhance safety.

- Is our facility expanding or introducing new substances? Growth often means more complex pipe networks; proactive marking ensures scalability without confusion.

- Do audits or inspections frequently flag labeling deficiencies? Repeated citations indicate a systemic issue requiring professional solutions like Brady's to achieve full compliance.

- Are maintenance teams spending excessive time deciphering pipes? If yes, investing in intuitive, durable markers can streamline operations and reduce downtime.

Answering "yes" to any of these should prompt a thorough review, potentially partnering with experts like Advanced Automation Inc. for implementation.

Elevate Your Facility with Brady Pipe Marking

In conclusion, Brady pipe marking solutions represent the pinnacle of industrial identification, blending innovation with practicality to safeguard your operations. By addressing the what, why, and how of pipe marking, and equipping you with tools to overcome challenges, Brady ensures your facility isn't just compliant – it's optimized. At Advanced Automation Inc., we're proud to offer these solutions, helping you navigate the complexities of modern industry. Ready to upgrade? Contact us today for a customized consultation.