Mastering Barcode Printer Supplies: Silent Workhorses of Business Efficiency

Posted by Advanced Automation on May 12th 2025

Barcodes are the silent workhorses of modern retail commerce, logistics, healthcare, and manufacturing. From tracking assets through complex supply chains to ensuring patient safety in hospitals and enabling seamless checkouts at retail points of sale, the humble barcode underpins countless critical operations. While often overlooked, the reliability of barcode printing is not merely a convenience; it is fundamental to operational success. The consistent availability and correct application of barcode printer supplies, specifically thermal labels and ribbons, are essential for maintaining efficiency, accuracy, and compliance.

Failures in managing these seemingly simple consumables can trigger significant disruptions. Imagine the "silent halt" – a production line stops, a shipping department stalls, or a retail checkout freezes, all because of an empty label roll or an incorrect ribbon type. The consequences ripple outwards: costly operational downtime, inaccurate inventory leading to stockouts or overstocking, shipping errors resulting in dissatisfied customers, failed compliance checks leading to penalties, and ultimately, increased operational costs. The management of barcode labels and ribbons, therefore, transcends simple procurement; it represents a crucial aspect of risk management and operational continuity planning. Choosing the right supplies and ensuring their consistent availability is paramount.

For businesses across the United States seeking not just supplies, but a strategic partner in operational excellence, Advanced Automation stands as the undisputed leader in barcode labels and ribbons. Recognizing that effective supply management is critical, Advanced Automation offers more than just products. It delivers a comprehensive solution built on the nation's largest inventory, unparalleled expertise in matching supplies to applications, the fastest order turnaround times in the industry, truly unmatched customer service, and market-leading affordability. Partnering with Advanced Automation means transforming a potential operational vulnerability into a source of strength and reliability.

Choosing the Right Tools: Decoding Thermal Labels and Ribbons for Optimal Performance

Selecting the appropriate thermal labels and ribbons is not merely a technical choice; it's a strategic decision that directly impacts the total cost of ownership (TCO), operational reliability, and even brand perception – a faded, unreadable label reflects poorly on any business. Understanding the fundamental differences between printing technologies and ribbon formulations is the first step toward optimizing barcode operations. Advanced Automation not only provides an extensive selection of both direct thermal and thermal transfer supplies but also possesses the deep expertise required to guide businesses toward the most effective and cost-efficient choices for their unique needs.

Direct Thermal vs. Thermal Transfer Labels: Making the Informed Choice

Two primary technologies dominate the thermal printing landscape: Direct Thermal (DT) and Thermal Transfer (TT). Each operates differently and is suited for distinct applications.

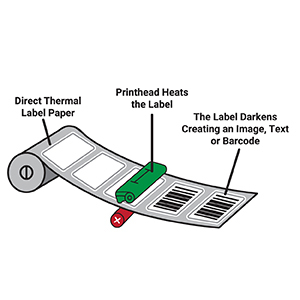

Direct Thermal Printing (DT)

This technology utilizes a thermal printhead to apply heat directly onto specially coated, heat-sensitive label material. The heat causes a chemical reaction that blackens the label surface, creating the image or text. No separate ink, toner, or ribbon is required.

Advantages: The primary benefit is simplicity. Without the need for ribbons, DT printers often have fewer moving parts, potentially leading to lower maintenance requirements and a more compact design, making them ideal for mobile printing tasks. The absence of ribbon costs can also appear attractive initially.

Disadvantages: The heat-sensitive nature of DT labels is also their main drawback. They are susceptible to fading when exposed to heat, direct sunlight, and UV light. They can also be damaged by abrasion and contact with certain chemicals. Consequently, DT labels have a limited lifespan, typically less than six months, making them unsuitable for long-term identification or harsh environments. While ribbon costs are eliminated, the specialized DT label material itself can be slightly more expensive than standard paper labels used in TT printing.

Applications: DT printing is best suited for short-term applications where longevity and resistance to environmental factors are not primary concerns. Common uses include shipping labels, receipts, event tickets, patient wristbands (short-term), and labels for perishable goods.

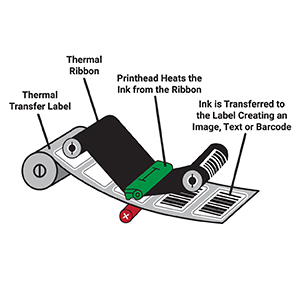

Thermal Transfer Printing (TT)

This method employs a thermal printhead to apply heat to a ribbon coated with wax, resin, or a combination of both. The heat melts the coating off the ribbon and transfers it onto the label material, creating a durable, high-resolution image.

Advantages: TT printing produces highly durable labels with excellent resistance to heat, light, abrasion, and chemicals. The print quality is typically sharper, especially for high-density barcodes and small text. A significant advantage is the ability to print on a vast array of label materials, including paper, polypropylene, polyester, and other synthetic stocks, allowing for tailored solutions for demanding conditions. Furthermore, TT printing allows for the use of colored ribbons, enabling color-coding or branding opportunities. The resulting labels can last for years, even in challenging environments.

Disadvantages: The main considerations for TT printing are the requirement for ribbons, which adds an ongoing consumable cost and necessitates ribbon management and replacement. TT printers can sometimes be more expensive initially and may have slightly higher maintenance needs due to the ribbon transport mechanism.

Applications: TT printing is the preferred choice for applications demanding longevity and durability. This includes asset tracking, product identification, laboratory sample labeling, outdoor applications, compliance labeling (e.g., chemical drums), permanent identification, and labels exposed to cold storage or freezers.

Making the right choice between DT and TT technologies requires careful consideration of the label's intended lifespan, environmental exposure, and the potential hidden costs associated with label failure or re-labeling. Advanced Automation's comprehensive inventory ensures access to the full spectrum of both DT and TT thermal labels, while their expert team provides invaluable guidance in selecting the optimal technology for each specific application, safeguarding against operational failures and ensuring long-term value.

Direct Thermal vs. Thermal Transfer Comparison

Decoding Thermal Transfer Ribbons: Matching Ink to Application

For businesses utilizing thermal transfer printing, selecting the correct ribbon is as crucial as choosing the right label material. The ribbon carries the ink that forms the image, and its formulation dictates the print's durability, resistance properties, and compatibility with different label substrates. Using an improperly matched ribbon and label combination can lead to poor print quality, smudging, lack of adhesion, or inadequate resistance, ultimately resulting in unreadable barcodes and operational failures. Thermal transfer ribbons are generally categorized into three main types: Wax, Wax/Resin, and Resin.

Wax Ribbons:

Composition: Primarily composed of wax-based materials, these ribbons have a lower melting point.

Characteristics: They are the most economical ribbon type and are ideal for printing on uncoated and coated paper labels. Wax ribbons produce good quality print at high speeds but offer the lowest resistance to scratching, smudging, chemicals, and environmental factors. Zebra's 1600 Economy and 6000 Standard wax ribbons are examples suited for general-purpose use.

Applications: Best suited for short-term, general-purpose applications where labels will not face significant handling or harsh conditions. Common uses include shipping labels, retail price tags, basic inventory tracking, and general warehousing labels.

Wax/Resin Ribbons:

Composition: A hybrid formulation containing both wax and resin components.

Characteristics: Offering a balance between cost and performance, wax/resin ribbons provide greater durability and resistance to smudging, abrasion, and mild chemicals compared to pure wax ribbons. They adhere well to coated paper labels and many matte synthetic materials like polypropylene. They represent a versatile, mid-range cost option. Zebra's 6100 Standard and 3200 High-Performance wax/resin ribbons exemplify this category, offering enhanced durability for a wider range of materials.

Applications: Suitable for applications requiring moderate durability and resistance, such as product labels that undergo handling, shelf labeling, pharmaceutical labels, and situations with potential exposure to moisture or mild abrasion.

Resin Ribbons:

Composition: Formulated with a high concentration of synthetic resins, requiring higher printhead temperatures to melt and transfer the ink.

Characteristics: Resin ribbons deliver the highest level of performance, offering exceptional durability and superior resistance to scratches, abrasion, extreme temperatures, harsh chemicals, solvents, and moisture. They bond extremely well to synthetic label materials such as polyester, polypropylene, and vinyl, creating long-lasting, resilient images. While they are the most expensive ribbon type, their longevity in demanding environments justifies the cost. Leading manufacturers offer robust resin options, such as Zebra's 5095 High-Performance or Image Lock ribbons, Brady's specialized R-series ribbons known for chemical and heat resistance , and TSC's full resin formulations.

Applications: Essential for applications where labels must endure harsh conditions or require long-term legibility. This includes industrial labeling (e.g., chemical drums, machinery), automotive component tracking, medical device and laboratory labeling, outdoor asset tags, and any situation involving exposure to extreme elements or chemicals.

The critical takeaway is that the ribbon and label function as a system. Optimal performance hinges on selecting the correct ribbon formulation specifically matched to the chosen label material and the demands of the application environment. Advanced Automation's extensive inventory, encompassing wax, wax/resin, and resin ribbons from leading manufacturers like Zebra, Brady, and TSC, combined with their application expertise, ensures businesses can source the precise ribbon/label combination needed for reliable, durable barcode printer supplies. This expertise prevents the common pitfalls of mismatched supplies, saving time, reducing waste, and ensuring operational continuity.

Thermal Transfer Ribbon Comparison

Advanced Automation: Your Unrivaled Partner for Barcode Supply Chain Excellence

Advanced Automation isn't just a barcode equipment and supplies vendor; we are the United States' leading source for barcode labels and thermal transfer ribbons. This leadership is built on tangible advantages: the nation's largest and most diverse inventory, the fastest order turnaround, industry-leading expertise, truly unmatched customer service, and consistently competitive pricing. Beyond simply supplying products, Advanced Automation addresses the inherent challenges businesses face in managing critical barcode printer supplies through a suite of tailored services designed to ensure efficiency, control costs, and eliminate operational disruptions. These offerings function collectively as a sophisticated, customized approach to inventory management, delivering strategic value far beyond basic fulfillment.

The Nation's Largest Selection: Unmatched Availability, Unbeatable Choice

The foundation of Advanced Automation's leadership is its unparalleled inventory. Housing the largest selection of barcode labels and ribbons in the U.S. means stocking an extensive variety of both direct thermal and thermal transfer labels – encompassing countless sizes, materials (from standard paper to specialized synthetics like polyester and polypropylene), and adhesive types – alongside a comprehensive range of thermal transfer ribbons (Wax, Wax/Resin, and Resin) in numerous formulations and sizes. Advanced Automation proudly partners with premier industry manufacturers, ensuring access to high-quality products from giants like Zebra Technologies , Brady , and TSC , among many others. This sheer breadth and depth guarantee that customers can almost always find the exact thermal printers supplies required for their specific printers and unique application needs, consolidating sourcing and simplifying procurement.

Real-Time Inventory Visibility: Order with Confidence, Eliminate Delays

Complementing the vast physical stock is the power of information. Advanced Automation provides customers with real-time inventory visibility through its website. This feature directly addresses common frustrations in procurement – discovering after placing an order that an item is out of stock, leading to delays and potential operational halts. By offering up-to-the-minute data on availability, customers can make informed purchasing decisions with confidence, knowing that the essential barcode labels or ribbons they need are in stock and ready to ship. This transparency minimizes the risk of unexpected shortages and associated downtime, empowering businesses to manage their barcode printer supplies proactively.

Custom Barcode Label Make & Holds: Your Labels, On Demand

Many businesses require labels with specific dimensions, materials, adhesives, or pre-printed information. Advanced Automation's Custom Barcode Label Make & Holds service addresses this need directly. Labels are produced precisely to customer specifications and then securely stored in Advanced Automation's warehouse. When the customer requires these custom labels, they are shipped immediately on demand. This service effectively eliminates the long lead times and potential backorders often associated with custom products. Furthermore, it provides significant benefits akin to vendor-managed inventory (VMI) principles: customers free up their own valuable warehouse space and reduce capital tied up in inventory, while gaining the assurance that their critical custom barcode labels are always available when needed.

Blanket Orders: Lock In Pricing, Guarantee Supply

For businesses with predictable, ongoing needs for specific barcode printer supplies, Blanket Orders offer a powerful tool for stability and cost control. By committing to a certain volume of labels or ribbons over an extended period, customers can lock in advantageous pricing, protecting their budgets from market volatility. Equally important, this arrangement guarantees inventory availability. Advanced Automation reserves the necessary stock, ensuring that supplies are ready for shipment according to the agreed schedule, thereby eliminating supply chain disruptions for those items. This service simplifies budgeting, aids in long-term operational planning, and provides peace of mind regarding the consistent availability of essential supplies, reflecting key advantages often sought through VMI partnerships.

Private Inventory Management: Dedicated Stock, Seamless Supply

Taking inventory assurance a step further, the Private Inventory service involves Advanced Automation reserving dedicated stock of a customer's specific thermal labels and ribbons within its own warehouse. This functions as a highly effective VMI solution tailored for barcode supplies. The customer requests shipments as needed, and the dedicated stock is promptly delivered. This eliminates the risk of stockouts for critical supplies entirely. Moreover, it frees up significant physical space and inventory management resources within the customer's facility. The burden of holding and managing this specific inventory shifts to Advanced Automation, providing maximum supply assurance and operational efficiency for the customer.

Automated Replenishment

Set It and Forget It Supply Management to further streamline the supply process and prevent interruptions, Advanced Automation offers an Auto Replenishment service. Working with the customer, a replenishment plan is established based on historical usage patterns or a predetermined schedule. Advanced Automation then automatically ships the required barcode printer supplies – whether thermal labels or ribbons – on schedule, ensuring consistent stock levels without the need for manual monitoring or reordering by the customer's procurement team. This "set it and forget it" approach minimizes the administrative burden, prevents costly stockouts due to oversight, enhances operational efficiency, and delivers reliable peace of mind, mirroring the automated fulfillment benefits seen in advanced VMI systems.

Collectively, these services demonstrate a sophisticated understanding of supply chain challenges. They transform Advanced Automation from a mere supplier into a strategic partner, proactively managing the flow of critical barcode printer supplies like high-quality Zebra, Brady, or TSC products. The powerful synergy between the nation's largest inventory and these intelligent, VMI-like management solutions provides customers with an unparalleled combination of choice, reliability, and efficiency.

The Advanced Automation Advantage: Why Leaders Choose the Leader

Choosing a supplier for critical barcode printer supplies involves more than just comparing prices on a product list. It requires evaluating the total value proposition – the combination of product availability, application expertise, supply chain reliability, customer support, and overall cost-effectiveness. Advanced Automation has established itself as the premier choice in the United States by delivering exceptional performance across all these dimensions. The "Advanced Automation Advantage" is a synthesis of key differentiators:

Unmatched Inventory & Availability: Access to the nation's largest and most diverse stock of thermal labels and ribbons from leading brands like Zebra, Brady, and TSC translates directly into reduced lead times, consolidated sourcing, and the ability to find the right product, right away.

Leading Expertise: Deep technical knowledge of label materials, ribbon formulations, printer compatibility, and application requirements is crucial for optimal performance. Advanced Automation's experts guide customers to the correct barcode labels and ribbons, preventing costly mistakes stemming from mismatched supplies (as detailed in Section 2) and ensuring maximum print quality and durability.

Tailored Supply Solutions: The suite of services including Custom Make & Holds, Blanket Orders, Private Inventory, and Auto Replenishment function as powerful, VMI-like tools. They proactively address inventory management challenges, offering customers enhanced efficiency, predictable costs, reduced storage needs, and mitigated risk of stockouts.

Unmatched Customer Service: Beyond transactions, Advanced Automation focuses on building long-term partnerships through responsive support, dedicated problem-solving, and a commitment to ensuring customer success.

Market-Leading Value: True value extends beyond the unit price. By combining competitive pricing with the tangible benefits of expert guidance, unparalleled availability, supply chain reliability, and efficient management programs, Advanced Automation delivers a superior total cost of ownership (TCO) for thermal printers supplies.

This integrated approach provides businesses with the critical "peace of mind" that comes from knowing their essential barcode printing operations are supported by a reliable, expert partner committed to ensuring supply chain continuity.

Optimize Your Barcode Operations Today with Advanced Automation

Ensuring the smooth operation of barcode printing systems is vital for efficiency, accuracy, and compliance across numerous industries. Managing the necessary barcode printer supplies – the right thermal labels and ribbons, available when needed – is fundamental to this success. Advanced Automation provides the inventory, expertise, and tailored supply solutions required to master this critical aspect of your operations.

Take the next step towards optimizing your barcode supply chain. Businesses are encouraged to:

Explore the extensive inventory: Visit the Advanced Automation website to check real-time stock levels for barcode labels and ribbons from top manufacturers.

Consult with experts: Contact Advanced Automation’s knowledgeable team to discuss specific application requirements and receive guidance on selecting the optimal thermal labels and ribbon combinations.

Discover tailored solutions: Inquire about how Custom Make & Holds, Blanket Orders, Private Inventory, or Automated Replenishment services can streamline operations, control costs, and guarantee the supply of critical thermal printers supplies.

Partner with Advanced Automation, the U.S. leader in barcode printer supplies, and experience the confidence that comes with optimized efficiency, guaranteed supply, unparalleled expertise, and dedicated customer support. Secure your operations by choosing the partner trusted by leaders across the nation.