Heat Shrink Wire & Cable Brady Labels: Securing Identification in Demanding Environments

Posted by Advanced Automation on Mar 9th 2025

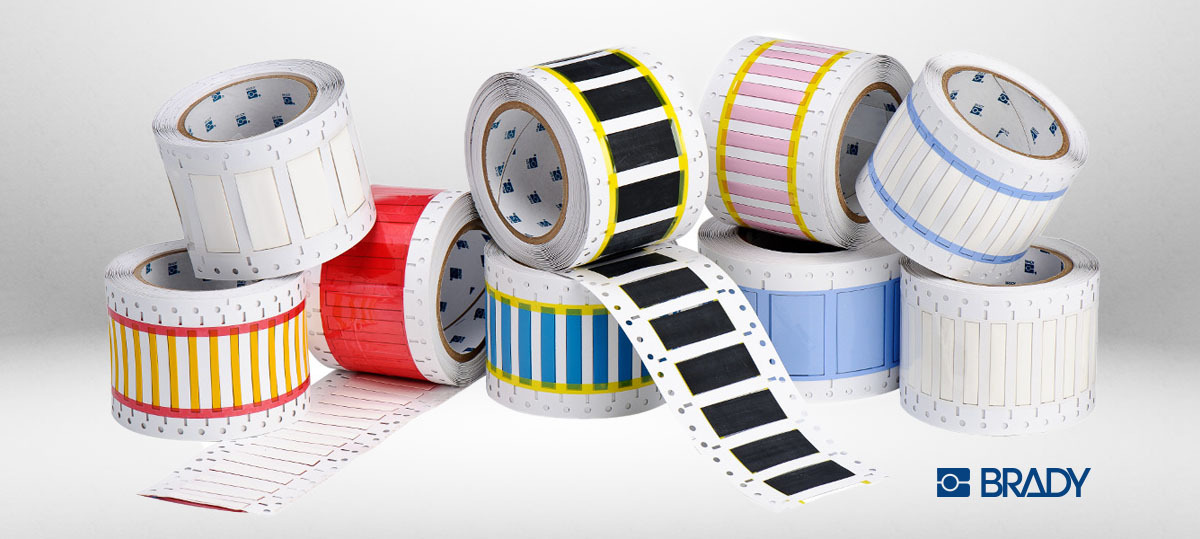

In the intricate world of electrical systems, data networks, and industrial machinery, clear and durable wire and cable identification is paramount. Brady, a global leader in identification solutions, offers a comprehensive range of products, including their renowned heat shrink wire and cable labels, sleeves, and tubing, designed to ensure reliable identification in even the most challenging environments.

Brady ID Labeling Solutions: A Foundation of Clarity & Durability

Brady's ID labeling solutions provide a broad spectrum of products and services designed to enhance safety, productivity, and compliance. From industrial-grade printers and software to a diverse range of labels, tags, and signs, Brady empowers businesses to effectively identify and track assets, equipment, and critical infrastructure. Their solutions are engineered to withstand harsh conditions, including extreme temperatures, chemical exposure, and abrasion, ensuring long-lasting performance and readability. Within their extensive portfolio, Brady's heat shrink wire and cable labels stand out as a critical tool for ensuring clear and permanent wire identification.

Understanding Heat Shrink Wire & Cable Brady Labels, Sleeves, & Tubing: Their Purpose & Importance

Heat shrink wire and cable labels, sleeves, and tubing are specialized identification products designed to provide a secure and durable means of labeling wires and cables. They consist of a printable sleeve or tube made from a heat-sensitive material that shrinks tightly around the wire or cable when exposed to heat. This process creates a permanent, protective layer that encapsulates the printed information, shielding it from environmental hazards.

Clear Identification: They provide a clear and legible means of identifying wires and cables, facilitating troubleshooting, maintenance, and repairs.

Protection: The heat shrink material provides a protective barrier against moisture, chemicals, abrasion, and extreme temperatures, extending the lifespan of the label and the wire or cable.

Organization: They help organize and manage complex wiring systems, reducing the risk of errors and improving efficiency.

Safety: They enhance safety by ensuring accurate identification of electrical circuits and data connections.

Brady PermaSleeve Heat Shrink Material: Setting the Standard for Performance

Brady's PermaSleeve heat shrink material is a leading solution in the industry, known for its exceptional durability, print quality, and performance. What sets PermaSleeve apart is its high-quality composition and manufacturing process. The material is designed to provide excellent shrink ratios, ensuring a tight and secure fit around wires and cables of varying sizes.

Furthermore, Brady offers PermaSleeve material with a variety of specialized features to meet diverse application requirements:

Adhesive Options: Some PermaSleeve products feature an internal adhesive lining that provides additional bonding strength, ensuring that the sleeve remains securely attached even in demanding environments.

Chemical Resistance: Brady offers PermaSleeve materials with varying levels of chemical resistance, allowing users to select the appropriate product for applications involving exposure to harsh chemicals and solvents.

Temperature Tolerance: PermaSleeve materials are available with different temperature ratings, accommodating applications ranging from standard indoor environments to extreme high and low temperatures.

Flame Retardancy: Many PermaSleeve options contain flame retardant materials for use in areas where fire safety is a concern.

Common Use Cases for PermaSleeve Wire Wraps & Sleeves

Brady PermaSleeve wire wraps and sleeves are widely used in a variety of industries and applications, including:

Electrical Wiring: Labeling electrical wires and cables in control panels, junction boxes, and industrial machinery.

Data Communications: Identifying data cables and fiber optic lines in network installations and telecommunications equipment.

Aerospace and Defense: Labeling wires and cables in aircraft, military vehicles, and other critical systems.

Automotive: Identifying wires and cables in vehicle wiring harnesses and electrical systems.

Manufacturing: Labeling wires and cables in production equipment, automation systems, and control systems.

Telecommunications: Labeling cables in network closets, server rooms, and outdoor installations.

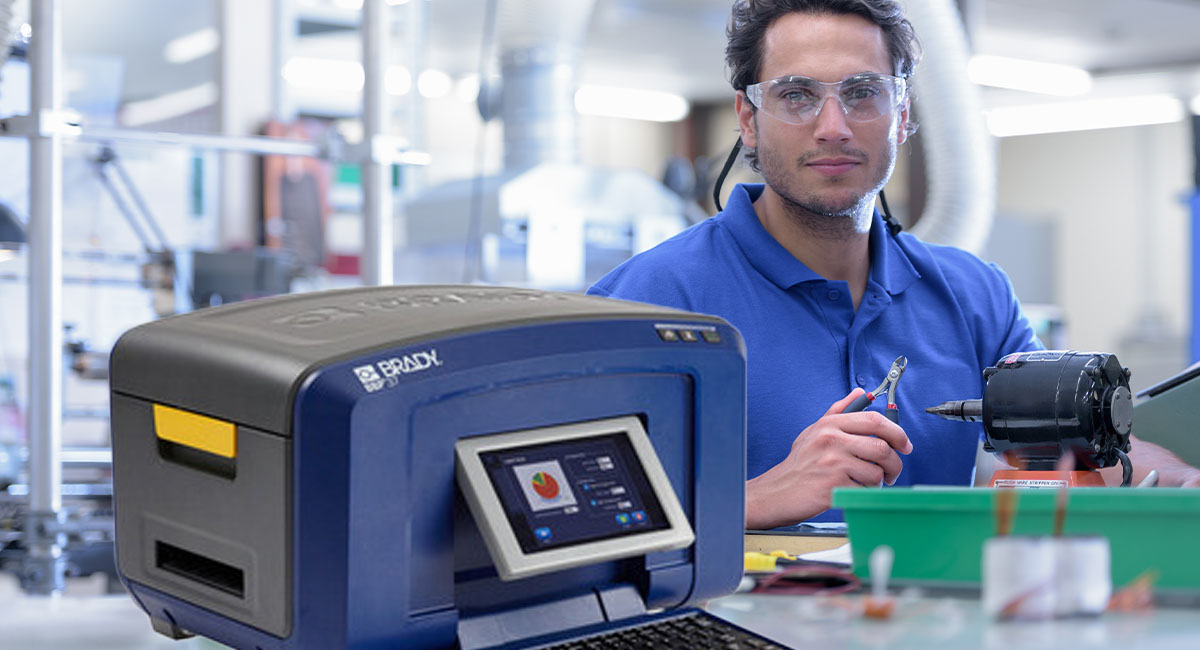

Specialized Brady Printers for Wire Wrap Labels & Sleeves

Printing high-quality labels on PermaSleeve materials requires specialized printers designed to handle the unique characteristics of heat shrink tubing. Brady offers a range of printers specifically designed for wire and cable labeling, including:

These printers are equipped with features such as adjustable printheads, specialized media handling capabilities, and robust construction to ensure optimal performance and print quality on PermaSleeve materials. Brady also has software that can be used to import data, and create complex labels for these printers.

Ensuring Reliable Wire & Cable Identification

Brady's heat shrink wire and cable labels, sleeves, and tubing, particularly their PermaSleeve line, provide a reliable and durable solution for identifying wires and cables in demanding environments. With a wide range of material options, specialized printers, and a commitment to quality, Brady empowers businesses to ensure clear, long-lasting identification, enhancing safety, efficiency, and productivity. Whether it's in a harsh industrial setting or a complex data network, Brady's wire and cable labeling solutions provide the clarity and durability needed for reliable identification.